Automatic Intelligent High Speed Paper Straw/Paper Tube/Paper Core Machine

Function Introduction: 1.19 type mini series paper straw machine,designing idea:Compact,Simple,Stability,High Speed,Inte

Basic Info.

| Model NO. | PT19-2010M |

| Weight | 1900kgs |

| PLC Controller | Delta |

| Function | Memory, Intelligent |

| After Service | Engineer Available Overseas |

| Speed | 100m/Min |

| Diameter | 5-20mm |

| Machine Type | Paper Straw Making Machine |

| Number of Layers | 3layers |

| Thickness | 0.5-1mm |

| Paper Material | 120g and 60g |

| Transport Package | Stretch Film |

| Specification | 3511*1265*1800mm |

| Trademark | JINSHEN |

| Origin | China |

| HS Code | 8441809000 |

| Production Capacity | 300sets/Year |

Product Description

Function Introduction:

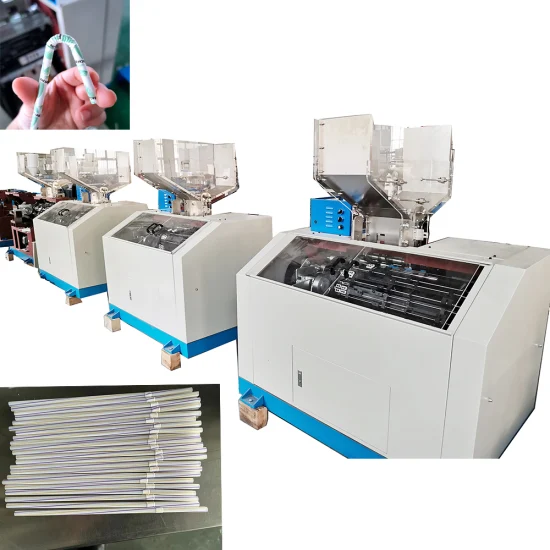

1.19 type mini series paper straw machine,designing idea:Compact,Simple,Stability,High Speed,Intelligence,Networking.2.Standard production for 1 Inch paper tube,thickness <1mm.3.Mainly used for paper straw making,cartridge tube etc,multi-section cutting.4.Food grade production standard.5.Spirally tube making from glue feeding,winder,final cutting

Features:

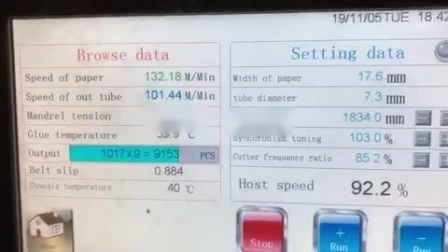

1.Body structure,Heavy-duty steel welded after NC cutting,Stable and Small Vibration.2.Paper stand,integral high speed design,constant paper tension control with Auto splicer3.Glue stand,glue temperature control,feeding amount control.4.Simple appearance,all motors put inside,make it easy for cleaning.5.Safety as the core design element,transformation part protected,covered with 1.2mm thick stainless steel.6.Stable,simple transformation principle,maintaining-free design,reduce maintaining frequency during operation.7.High speed,120m/min paper feeding,up to 100m/min tube production speed.8.Network,Industrial 485 cable,Ethernet cable,wireless WiFi network,4G network,and distributed control system.9.Intelligence,central monitoring,real monitoring run state of all equipments,production data can flow into ERP system for data collecting,Meanwhile,Engineer to be informed when machine has errors.

Main Technical Parameter

| Model | PAPER STRAW MACHINE PT19-2010M | ||

| Technical Parameter | Control System | ||

| Number of paper | 3layers | PLC Controller | Delta |

| Max-diameter | 20mm | Man-machine interface | Weinview touchscreen |

| Min-diameter | 5mm | Program edition | JS-NC5.0 |

| Min-thickness | 0.5mm | Servo system | Delta |

| Min length | 90mm | Actuator | CHNT |

| Output Speed | 100m/min | Max-length | 1200mm |

| Rewinding noses | Two noses/one belt | Signal component | Airtac |

| Cutting way | 10blades pneumatic | Synchronism control | Synchronous belt |

| Length fixation | Encoder | Synchronism tracking cutting system | Servo synchronized Tracking System |

| Operator | 1 person | Outfit assemble | |

| Way of shaft fixing | Pushing | Tube holder | Have |

| Speed control | Servo | Belt angle adjusting | Hand wheel adjustment |

| Power input | 3*380v(can be customized) | Belt tension adjusting | Hand wheel adjustment |

| Size(mm) | Stop when paper break(bottom) | Auto | |

| Mainframe size:L*W:H | 3511*1265*1800mm | Glue way | Glue roller(single and double) |

| Area space:L*W | 17000*6000mm | Lubrication | Electric roller |

| Wheel hub diameter | 215mm | Paper tension control | Constant tension control |

| Wheel hub height | 125mm | Paper stand | Auto splicer paper |

| Min-Tread | 320mm | Belt | Sailcloth |

| Max-Tread | 500mm | Enclosed Component | |

| Total Weight | 1900kgs | Mandrel | 1 set |

| Drive System | Belt | 1 pc | |

| Main power | 6.0KW(Servo motor) | Useful tool | 1 set |

| Max rotate speed of wheel hub | 200r/min | Air compressor | No |

| Output torque | 68N.M | ||

| Drive of wheel hub | 2 Wheel drive | ||

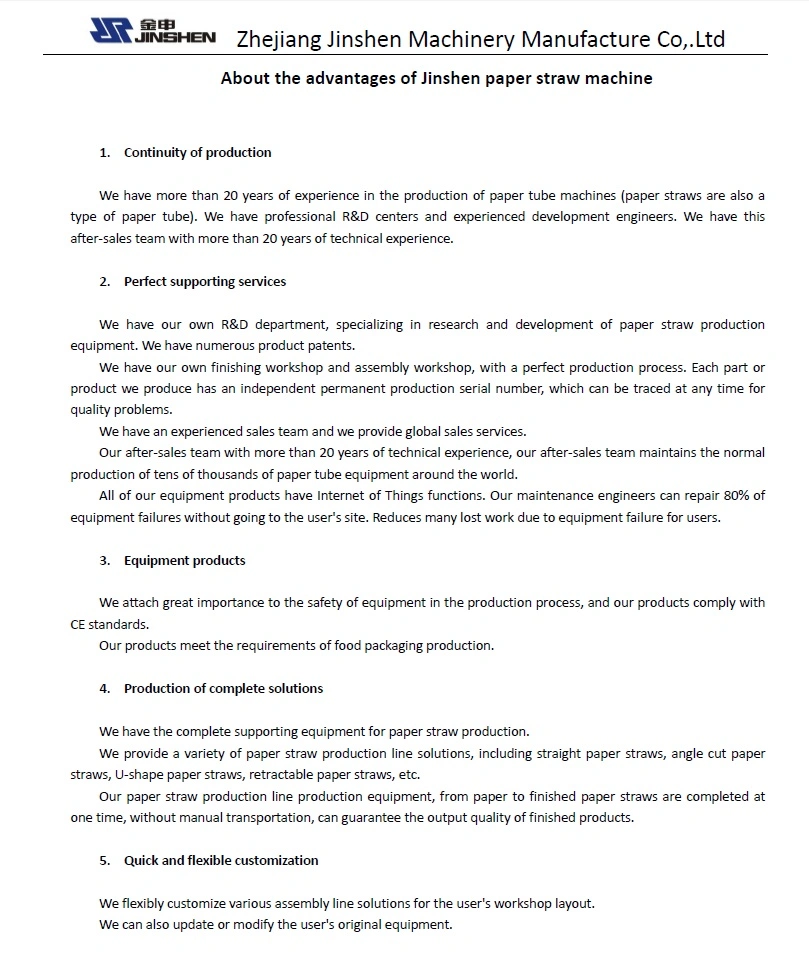

Company Profile:

Sample of paper straw:Shipping and packing:

Normally,we used stretch film pack goods.Also some are according to the customers requirement

Contact Information:Abby LeeZhejjiang Jinshen Machinery Manufacture Co.,Ltd.Add:No.689 qiushi road,Wutong Industrial Zone,Tongxiang City,Zhejiang Province,China 314500

Send to us